Equipment and expertise

EQUIPMENT AND EXPERTISE

Our know-how is based on human expertise is terms of qualifications and commitment which daily demonstrates the involvement and enthusiasm of our teams: whether for the manufacture of composite parts in polyester, carbon or kevlar, we do everything on a daily basis to respect precise specifications and tolerate no defects.

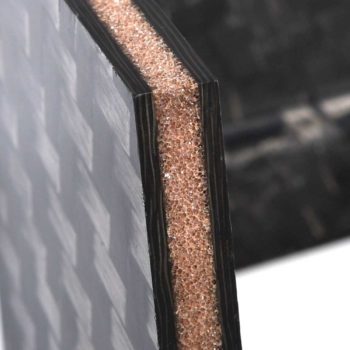

The search for excellence is our guideline for the many activities of the group incorporating glass fibre processes, including compaction. Our know-how is based on human expertise is terms of qualifications and commitment which daily demonstrates the involvement and enthusiasm of our teams. Whether for the manufacture of composite parts in polyester, carbon or kevlar, we do everything on a daily basis to respect precise specifications and tolerate no defects. The search for excellence is our guideline for the many activities of the group incorporating glass fibre processes, including the compaction of kevlar and carbon cloth, contact moulding, moulding of all composite parts, RTM injection and infusion moulding.

We also provide cutting-edge industries and startups with prototypes or common parts cut from flexible composite materials in carbon, leather, fibre, prepreg, foam etc.

With our integrated subsidiary T.S.I. (Techni Service Industrie), our latest-generation equipment enables us to produce any type of electric cabling and electronic board programming, but also mechanical assembly, riveting and crimping with micron-scale precision associated with perfect mechanical metrics.

This is true for the fitting of all types of mechanical parts and includes all metals from the most precious to the most common. The deburring of aluminium and titanium parts also characterises our know-how and the expertise of our teams, who are totally committed to our prestigious industrial clientele.

3D knitting and wire coiling are representative of our service-based productions organised into different centres of expertise focused on a single objective: customer satisfaction.

Equipped to face major challenges, we possess several “Zund” digital cutters equipped with mechanical blades, as well as spray paint booths for composite materials like aluminium and titanium.

EQUIPMENT AND EXPERTISE

Our know-how is based on human expertise is terms of qualifications and commitment which daily demonstrates the involvement and enthusiasm of our teams: whether for the manufacture of composite parts in polyester, carbon or kevlar, we do everything on a daily basis to respect precise specifications and tolerate no defects.

The search for excellence is our guideline for the many activities of the group incorporating glass fibre processes, including compaction. Our know-how is based on human expertise is terms of qualifications and commitment which daily demonstrates the involvement and enthusiasm of our teams. Whether for the manufacture of composite parts in polyester, carbon or kevlar, we do everything on a daily basis to respect precise specifications and tolerate no defects. The search for excellence is our guideline for the many activities of the group incorporating glass fibre processes, including the compaction of kevlar and carbon cloth, contact moulding, moulding of all composite parts, RTM injection and infusion moulding.

We also provide cutting-edge industries and startups with prototypes or common parts cut from flexible composite materials in carbon, leather, fibre, prepreg, foam etc.

With our integrated subsidiary T.S.I. (Techni Service Industrie), our latest-generation equipment enables us to produce any type of electric cabling and electronic board programming, but also mechanical assembly, riveting and crimping with micron-scale precision associated with perfect mechanical metrics.

This is true for the fitting of all types of mechanical parts and includes all metals from the most precious to the most common. The deburring of aluminium and titanium parts also characterises our know-how and the expertise of our teams, who are totally committed to our prestigious industrial clientele.

3D knitting and wire coiling are representative of our service-based productions organised into different centres of expertise focused on a single objective: customer satisfaction.

Equipped to face major challenges, we possess several “Zund” digital cutters equipped with mechanical blades, as well as spray paint booths for composite materials like aluminium and titanium.